Properly calibrating your T1 testers against NIST-traceable standards, verifying clock accuracy, signal power measurements, and pulse amplitude across the full dynamic range, will guarantee telecommunications excellence.

Uncalibrated equipment masks critical issues, generates false alarms, and jeopardizes regulatory compliance, while proper calibration enables proactive maintenance strategies and prevents costly network downtime. Environmental factors, power quality, and software configurations significantly impact calibration accuracy.

Understanding thorough calibration procedures will transform your network reliability and diagnostic capabilities.

Functions and Capabilities of T1 Testing Equipment

During field deployment considerations, you’ll appreciate portable designs that withstand harsh environmental conditions while delivering precise measurements. The equipment’s integration within the infrastructure allows seamless connectivity to various network elements, supporting all-encompassing performance monitoring throughout your telecommunications network.

These analyzers enforce quality assurance protocols by detecting timing errors, signal distortions, and protocol violations that could compromise network reliability and customer service quality.

Importance of Accurate Calibration in Telecommunications

The impact on network performance becomes immediately apparent when unconfigured equipment masks critical issues or generates false alarms. You’ll meet regulatory compliance needs only through adherence to calibration certification standards that demonstrate measurement traceability.

Proactive maintenance strategies rely heavily on precise diagnostic data that only properly adjusted analyzers can provide. While calibration cost-benefit considerations might initially seem burdensome, the expense pales compared to network downtime costs or regulatory penalties resulting from inaccurate measurements.

Calibration Preparation Requirements

Environmental condition assessment guarantees you’re working within specified temperature and humidity ranges that won’t jeopardize measurement integrity. Preparation checklist:

- Verify reference equipment certificates are current and traceable

- Assess ambient conditions for temperature stability (±5°C recommended)

- Review humidity levels to prevent condensation issues

- Confirm power quality meets equipment specifications

- Document baseline environmental readings

Equipment configuration review involves checking firmware versions, interface settings, and cable connections. Preliminary functional testing corroborates basic operations before formal calibration begins.

Calibration scheduling considerations include allowing adequate warm-up time and planning for potential equipment downtime during the process.

Detailed Calibration Procedure for T1 Testers

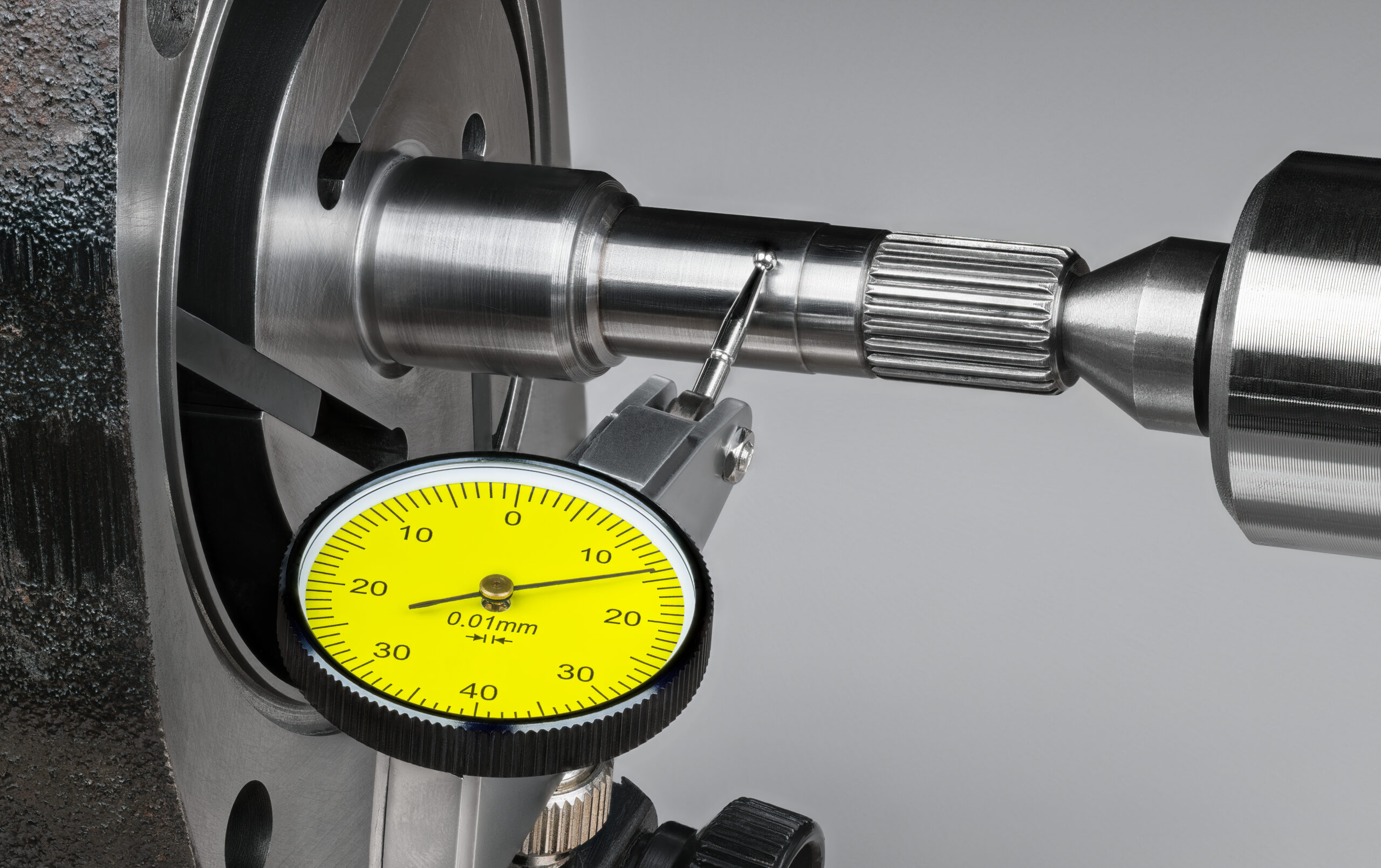

Systematic calibration begins with clock accuracy verification once your preparation phase confirms suitable conditions and equipment readiness. You’ll start by validating timing references against your NIST-traceable standards, guaranteeing precise synchronization across all test functions.

Next, you’ll perform signal power measurement calibration, adjusting output levels to match reference values within specified tolerances.

Clock recovery calibration follows, where you’ll verify the tester’s ability to accurately extract timing information from incoming signals. Pulse amplitude verification ensures your analyzer measures voltage levels correctly across the full dynamic range.

You’ll then calibrate pulse mask testing, confirming the equipment appropriately assesses signal quality against ITU-T G.703 specifications.

Finally, jitter and wander analysis calibration is conducted, validating measurement accuracy for short-term and long-term timing variations affecting network performance.

Addressing Common Calibration Challenges

Despite following proper calibration procedures, you’ll encounter specific challenges that can compromise T1 tester accuracy and reliability. These obstacles require strategic solutions to maintain measurement precision.

Common calibration challenges include:

- Signal integrity issues from impedance mismatches and cable degradation affecting measurement accuracy

- Power quality concerns, including voltage fluctuations and electrical noise interfering with calibration stability

- Environmental stressors such as temperature variations and humidity changes impact equipment performance

- Software calibration features requiring updates and proper configuration to maintain functionality

- User skill development gaps leading to improper procedures and inconsistent results

You’ll need to address interface compatibility problems between different equipment generations and timing reference instabilities. Jitter measurement calibration presents difficulties due to its sensitivity to external influences. Developing thorough troubleshooting protocols helps you identify and resolve these challenges efficiently.

Verification and Documentation Post-Calibration

Systematic verification confirms your T1 tester’s adjusted performance and guarantees that measurement accuracy meets telecommunications standards. You’ll conduct thorough post-calibration testing across all measurement functions, documenting results through calibration documentation archiving systems that maintain traceability records.

Implement test data trending analysis to identify performance patterns and potential drift indicators over time.

Your recalibration interval optimization depends on historical performance data and usage patterns. Verify that the technician training certification requirements for personnel handling verification procedures are met.

Establish quality control auditing procedures that validate calibration effectiveness and compliance with industry standards.

Certificate generation must include measurement uncertainties, environmental conditions, and reference standards used. You’ll maintain digital records accessible for regulatory inspections while tracking equipment performance metrics that inform future calibration scheduling decisions.

Between-Calibration Maintenance Practices

While formal calibration occurs at scheduled intervals, maintaining your T1 tester’s accuracy between calibrations requires consistent daily practices and proactive monitoring. These maintenance activities guarantee your equipment delivers reliable measurements and extend calibration intervals.

Essential between-calibration practices include:

- Daily self-test procedures – Run built-in diagnostics before each testing session

- Performance monitoring – Track measurement consistency and flag unusual readings

- Environmental protection – Store equipment in controlled temperature and humidity conditions

- Regular cleaning – Keep connectors and interfaces free from contamination

- Documentation tracking – Log usage patterns and any performance anomalies

Making minor adjustments within the manufacturer’s specifications helps maintain troubleshooting effectiveness. However, significant equipment configuration changes that could compromise calibration status should be avoided. When performance deviates drastically from baseline measurements, schedule immediate professional calibration rather than attempting corrections.

Professional vs. In-house Calibration: A Comparative Analysis

When adjusting your T1 testing equipment, you’ll choose between professional calibration services and establishing in-house capabilities. A thorough cost-benefit analysis reveals that professional services typically offer superior accuracy and compliance assurance. At the same time, in-house operations provide scheduling flexibility and potentially lower per-calibration costs for high-volume users.

Professional calibration brings specialized staff expertise and access to reference standards that most organizations can’t justify purchasing. These providers maintain rigorous quality assurance protocols and stay current with technological advancements in calibration techniques.

However, in-house calibration strengthens customer relationships by reducing equipment downtime and maintaining complete control over your calibration schedule. Your decision should weigh equipment volume, budget constraints, and the criticality of keeping telecommunications’ precise performance standards.

Implementing an Effective Calibration Program

Five essential components form the foundation of any successful T1 testing equipment calibration program. You’ll need to establish clear protocols that guarantee your telecommunications infrastructure maintains peak performance while meeting industry standards.

Your calibration program should include:

- Scheduling flexibility that accommodates operational demands without disrupting critical network functions

- Staff skill development through regular training on emerging calibration techniques and equipment updates

- Quality assurance metrics to track calibration accuracy and identify performance trends

- Continuous improvement process based on data analysis and industry best practices

- Customer feedback mechanisms to harmonize calibration services with actual field requirements

You must integrate these components systematically, creating documentation protocols that support compliance auditing. Regular program reviews ensure you adapt to technological changes while maintaining calibration excellence, which directly impacts your network’s reliability and performance.

Telecommunications Excellence Through Precise T1 Testing Equipment

T1 testers and analyzers are vital for maintaining telecommunications network integrity, ensuring compliance with industry standards, and providing accurate troubleshooting capabilities for critical infrastructure. Regular professional calibration of these sophisticated devices guarantees that clock accuracy, signal level measurements, BER testing functions, and frame structure analysis remain within specified tolerances, directly supporting network reliability and service quality.

Telecommunications professionals can confidently rely on their T1 testing equipment for critical network decisions and compliance verification by establishing a comprehensive calibration program with proper documentation and trained personnel. The cost of measurement errors in telecommunications infrastructure far exceeds the investment in proper calibration services.

Contact EML Calibration today to ensure your T1 testing equipment delivers the precision and reliability your telecommunications operations require. With ISO/IEC 17025:2017 accreditation, NIST traceable standards, and 25 years of specialized experience, EML Calibration provides convenient on-site and comprehensive laboratory calibration services that keep your critical telecommunications testing equipment performing at peak accuracy.