Unlock the secret to achieving impeccable precision with on-site torque calibration. Wave goodbye to uncertainty and unlock the potential of effortless accuracy. Click now to unveil the mystery!

Are you weary of the complexities and inconveniences of off-site torque calibration? Your search ends here! Picture this: skilled professionals arriving at your location, armed with state-of-the-art tools, to calibrate and fine-tune your equipment right where it operates. No more delays in shipping, no more interruptions in operations. Accept the benefits of on-site calibration and tuning to ensure your torque equipment performs at peak efficiency and fits perfectly with your workflow. Bid farewell to the headaches associated with off-site calibration and welcome to the age of seamless precision.

Benefits of Torque Calibration on-Site

Explore the world of torque calibration on-site and enjoy all of its benefits. The ability to do torque calibration on-site eliminates the need to ship equipment to an off-site location, which can result in significant cost savings. This saves money on transportation, minimizes delays throughout the calibration procedure, and recovers valuable time.

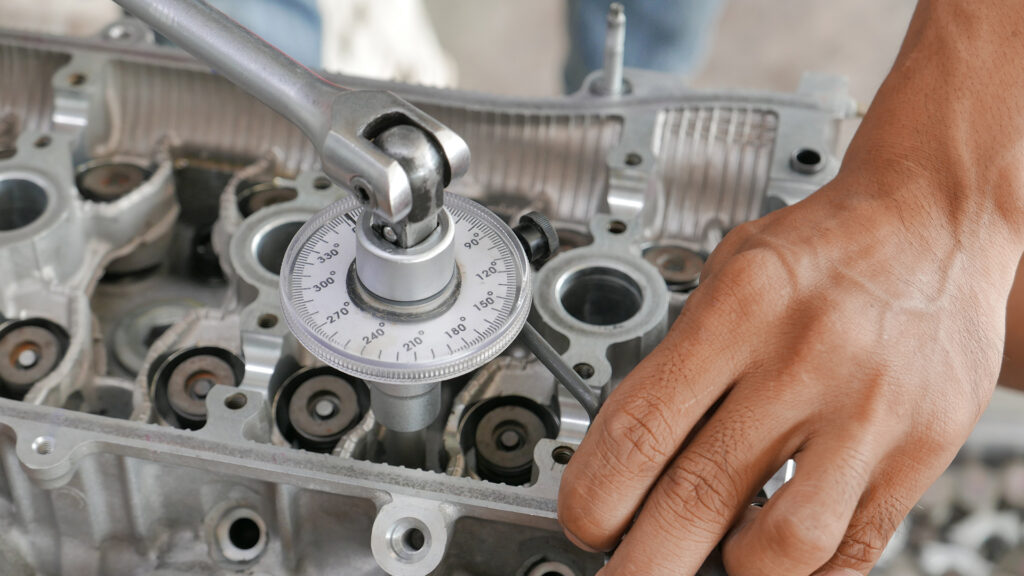

Within the corridors of your operating sanctuary, professionals perform their calibration process efficiently in the enchanted world of on-site calibration. Your workdays will be free of the threat of missing equipment since faster methods are used to change productivity results. Moreover, on-site calibration takes on the role of the equipment’s attentive sentinel, constantly listening and possessing an extraordinary ability to detect even the slightest indications of possible conflict or straying aberrations. Precision shines brilliantly as specialists work with state-of-the-art equipment and follow precise processes in steadfast calibration protocols to make every measurement a work of exactitude.

The Deep Importance of Accuracy in Torque Adjustment

The secret to constant performance and dependability is the meticulous skill of torque tuning. It is a lighthouse of significance that beams over many industrial landscapes, its influence tying financial prudence, accuracy, and efficiency into the very fabric of operations.

When you give your instruments the gift of precise torque calibration, you open up a world of consistency and dependability that keeps your efforts safe from the specter of redoing and the dark shadow of mistakes. Accurate torque calibration is a boon to equipment longevity. It protects against the dangerous extremes of over- and under-tightening, which reduces the likelihood of equipment breakdown and operational standstills.

Benefits of Torque Equipment On-Site Tuning

The tale of torque equipment on-site tuning creates a tapestry of benefits and improvements that give a priceless gift of increased performance and efficiency, smoothly traversing the many industry landscapes. This calibrating orchestration in your operational sanctuary offers temporal treasures, recovering the minutes previously lost on the grueling journey to far-off off-sites. The elusive dance of efficiency becomes a more comfortable companion, cutting the intervals of operational slumber.

Furthermore, since on-site tuning removes the need for shipment and lowers the possibility of damage during transit, it is a more affordable option. Users may guarantee better equipment performance, increasing accuracy and dependability by calibrating and fine-tuning torque equipment on-site. This procedure will also reduce downtime because there is no waiting period for equipment to return from an off-site calibration facility.

Uncovering Annual Mysteries with Torque Calibration and Tuning Odyssey

While in efficiency, one sets off on a voyage filled with recurring mysteries inside the complex world of torque equipment calibration and harmonization, which loom as the silent builders of precision. It is a surgical precision necessary when applying methods, a hunt for the key of unflinching exactitude. A dangerous tightrope walk ensues when the threat of torque standards occurs, causing defiance and interrupting the noble project of harmonization and calibration.

Frequently Asked Questions

How long could an on-site torque calibration take to complete?

The torque calibration procedure is usually carried out on-site over many hours. This painstaking process has several benefits, which include smooth equipment synchronization, increased procedural efficiency, and the comforting presence of seasoned professionals, all of which come together to bestow a cloak of effortless perfection onto your calibration requirements.

Can Any Torque Apparatus Benefit from On-Site Torque Calibration?

Almost every type of torque equipment can coexist peacefully with on-site torque calibration. Benefits are numerous, similar to the symphony of efficiency and the orchestration of increased precision. This calibration process may benefit industries as varied as manufacturing, the automobile sector, and the aerospace domain that explores the stratosphere. Consider the stars directing you while choosing one of these services: precise calibration and a smooth turnaround time.

Are there any special requirements or rituals that must be followed to plan and execute an on-site torque calibration?

Holy folders with the essential papers must be carefully prepared, and the watchful guardians of safety must be called in to stand sentinel before this sacred calibration ceremony can begin. Please ensure your torque equipment is ready for action before entering the wild world of training requirements. In addition, I set out to understand how to get to the sacred location as the calibrating symphony unfolds its beautiful picture.

In contrast to its remote off-site counterpart, what currency must one exchange for the privilege of on-site torque calibration?

The funds needed for on-site torque calibration usually exceed those required for its off-site relatives, primarily because of the distance traveled. However, the benefits discovered in the on-site domain—convenience, unwavering dependability, and the secret to customer satisfaction—balance the ostensibly higher cost of entry.

Do Physical Boundaries Place Their Limitations on the Scope of On-Site Torque Calibration Services?

Geographical factors can impact the availability of on-site torque calibration services. The noble duty may be partially embraced in distant hinterlands and under the control of multinational domains. Like guards at the entrance, these local enclaves could influence whether this complicated project is available.