You’ll maintain dial indicator accuracy by calibrating against certified gauge blocks or ring gauges, ensuring consistent environmental conditions to prevent thermal expansion errors, and using proper contact force with consistent approach angles. Watch for gear train wear, spindle damage, and contamination that compromise precision.

Professional calibration services provide traceable standards, controlled environments, and detailed uncertainty reports that satisfy quality audits. Document your calibration intervals based on usage patterns, perform multiple measurement cycles to verify repeatability, and you’ll uncover how to identify the subtle signs that signal when your indicator needs attention.

Understanding Dial Indicator Types and Their Measurement Applications

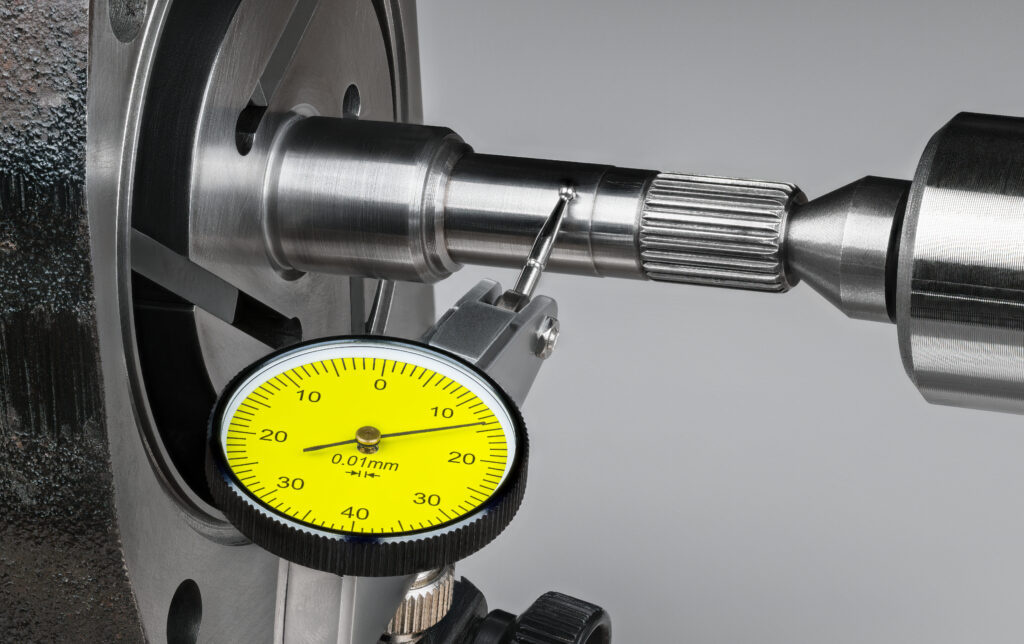

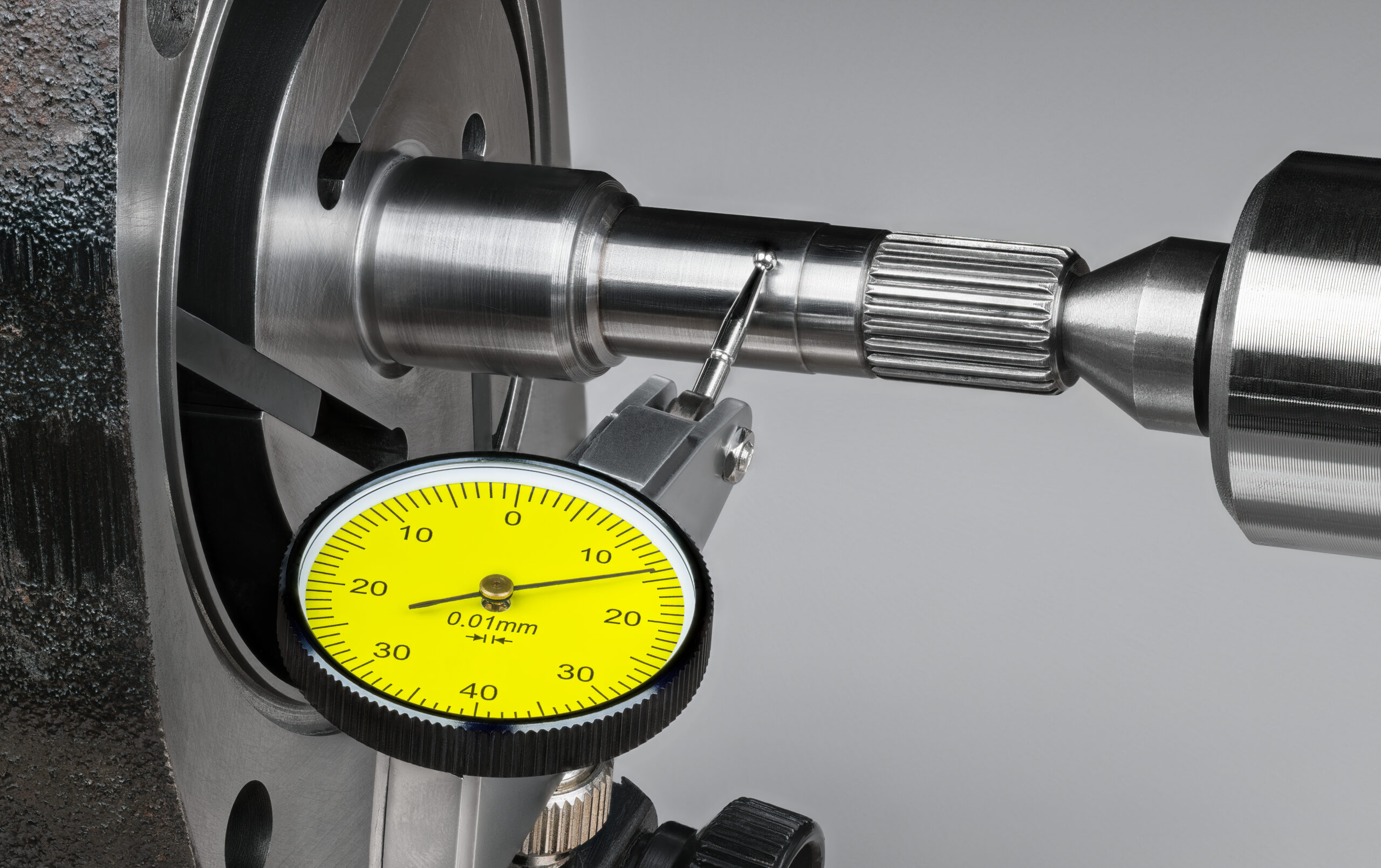

Dial indicators serve as essential tools for measuring small linear distances and variations in manufactured parts. You’ll find these instruments in quality control labs, machine shops, and manufacturing facilities where precision matters. When selecting a dial indicator, you need to evaluate the indicator dial resolution—typically ranging from 0.001″ to 0.0001″ depending on your application requirements.

Different indicator contact tips allow you to measure various part geometries, from flat surfaces to curved profiles. You’ll achieve measurement repeatability by properly performing zero point adjustment before each use.

Plunger-type indicators work best for straightforward linear measurements, while lever-style indicators excel in confined spaces. Test indicators provide exceptional sensitivity for setup work and part inspection. Understanding these differences helps you choose the appropriate tool for accurate, reliable measurements.

Essential Calibration Techniques for Dial Indicators

Before you can trust your dial indicator’s readings, you’ll need to verify its accuracy through systematic calibration procedures. Master gauge comparisons form the foundation of proper calibration, using certified gauge blocks or ring gauges as reference standards. You’ll position your indicator against these masters at multiple points throughout its measurement range to detect any deviations.

Don’t overlook thermal expansion effects—temperature variations can drastically alter readings. Maintain consistent environmental conditions during calibration, ideally at 68°F (20°C). Operator technique variations also influence results, so you should use consistent contact force and approach angles.

Document environmental conditions impact on your measurements, including humidity and temperature fluctuations. Perform multiple measurement cycles to establish repeatability, ensuring your dial indicator delivers reliable data for critical applications.

Common Issues That Compromise Dial Indicator Accuracy

When mechanical components within your dial indicator deteriorate, they’ll introduce systematic errors that compromise measurement reliability. Gear train wear creates backlash and inconsistent readings, while spindle damage affects linear movement precision. You’ll also encounter accuracy problems from temperature effects—thermal expansion alters both your instrument and measured parts, causing significant deviations in critical measurements.

Environmental contamination poses serious risks. Dust, moisture, and machining fluids infiltrate internal mechanisms, accelerating wear and causing binding. Your operator technique directly impacts results too; improper mounting force, incorrect stylus contact, and inconsistent reading angles generate false data.

Storage conditions matter considerably. Exposing indicators to humidity, extreme temperatures, or mechanical shock between uses degrades calibration stability. Regular verification against certified standards helps you identify these issues before they compromise your quality control processes.

Why Professional Calibration Services Deliver Superior Results

Given these numerous accuracy threats, professional calibration services provide measurement certainty that in-house methods can’t match. You’ll benefit from controlled instrument environment conditions that eliminate temperature and humidity variables affecting readings. Accredited labs like EML use certified reference standards traceable to national standards, ensuring your dial indicators meet specifications.

They’ll establish the ideal calibration interval based on your usage patterns and performance history, preventing unexpected measurement failures. Professional services provide thorough calibration data documentation that satisfies quality audits and regulatory requirements. Most importantly, you’ll receive detailed uncertainty calculation reports that assess measurement confidence levels—critical information for tolerance-sensitive applications.

This mathematical analysis accounts for all error sources, giving you defensible measurement results that protect product quality and reduce liability risks.

Protect Your Precision with EML Calibration’s Dial Indicator Services

You’ve invested in quality measuring tools—now protect that investment through regular calibration. Don’t let uncalibrated dial indicators compromise your quality control or risk costly production errors. Schedule professional calibration services to maintain measurement accuracy, meet compliance requirements, and keep your operations running smoothly. When you’re working within tight tolerances, there’s no room for guesswork. Make calibration a cornerstone of your quality assurance program, and you’ll maintain the precision your processes demand.

EML Calibration provides ISO/IEC 17025:2017 accredited dial indicator and bore gauge calibration with NIST traceable standards and over 25 years of metrology expertise. Whether you need on-site service or laboratory calibration, we deliver the precision and documentation your quality program requires. Contact us today to schedule your calibration service and ensure your measurements remain accurate and reliable.