Professional caliper calibration services verify accuracy across digital, dial, and vernier types through multi-point testing at 0%, 25%, 50%, 75%, and 100% of capacity against NIST-traceable standards. You’ll need calibration to detect battery drift in digital models, gear mechanism wear in dial calipers, and jaw degradation that causes measurement errors. Accredited ISO/IEC 17025 services provide documented traceability without requiring you to invest in expensive gauge blocks or maintain in-house expertise. Continue below to uncover which failure modes threaten your specific caliper type and whether outsourcing makes financial sense.

Why Your Caliper Measurements Might Be Wrong

Even when you’re following proper measurement techniques, your caliper readings can be surprisingly inaccurate. Several factors contribute to measurement uncertainty beyond obvious problems. Improper usage techniques like excessive measuring force or incorrect jaw placement create systematic errors you mightn’t notice.

Environmental factors play a vital role—temperature fluctuations cause metal expansion, while humidity and dust contaminate sliding surfaces. Your storage conditions matter too; leaving calipers in toolboxes without protection allows corrosion and physical damage.

Human error extends beyond technique—you’re reading parallax angles incorrectly on dial models or misinterpreting digital displays. Battery drain in digital calipers causes erratic readings before complete failure. Without regular calibration verification, you can’t distinguish between these variables, making every measurement questionable regardless of your skill level.

Which Caliper Types Need Professional Calibration?

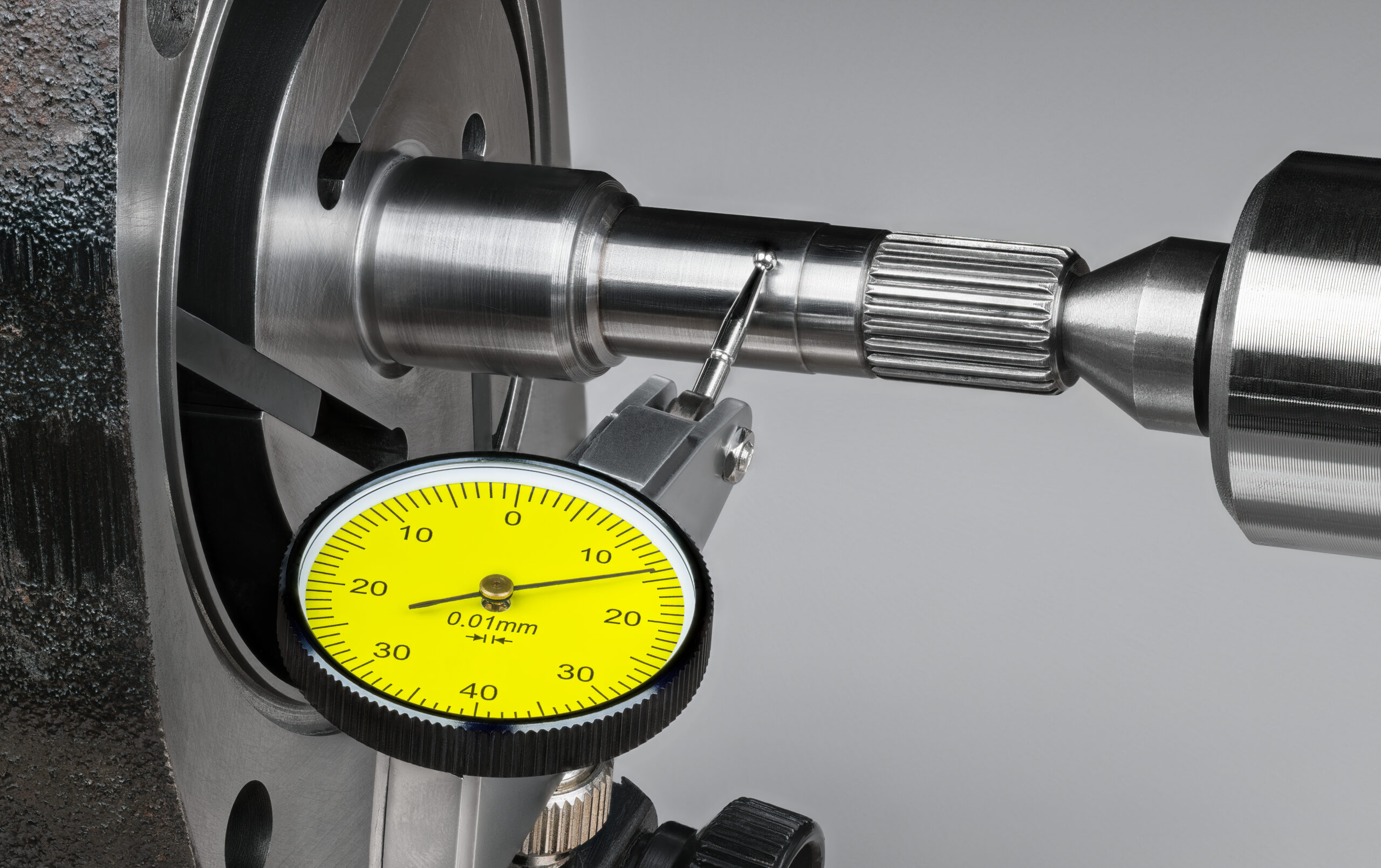

All calipers—vernier, dial, and digital—require professional calibration to maintain measurement integrity. Digital caliper calibration addresses electronic drift and battery-related accuracy issues that affect LCD readings.

Dial caliper calibration verifies gear mechanism precision and indicator accuracy throughout the measurement range. Vernier caliper calibration guarantees scale alignment and readability remain within specification.

Your precision caliper calibration needs extend beyond basic types to specialty instruments, including inside calipers, outside calipers, and depth-measuring variants. Analog caliper calibration encompasses both vernier and dial types, requiring expertise in mechanical component verification.

Don’t assume newer instruments need less attention—manufacturing tolerances and initial quality vary tremendously. Whether you’re using budget models or premium brands, professional calibration confirms actual performance against stated specifications, protecting your quality control processes.

Inside the Multi-Point Verification Process

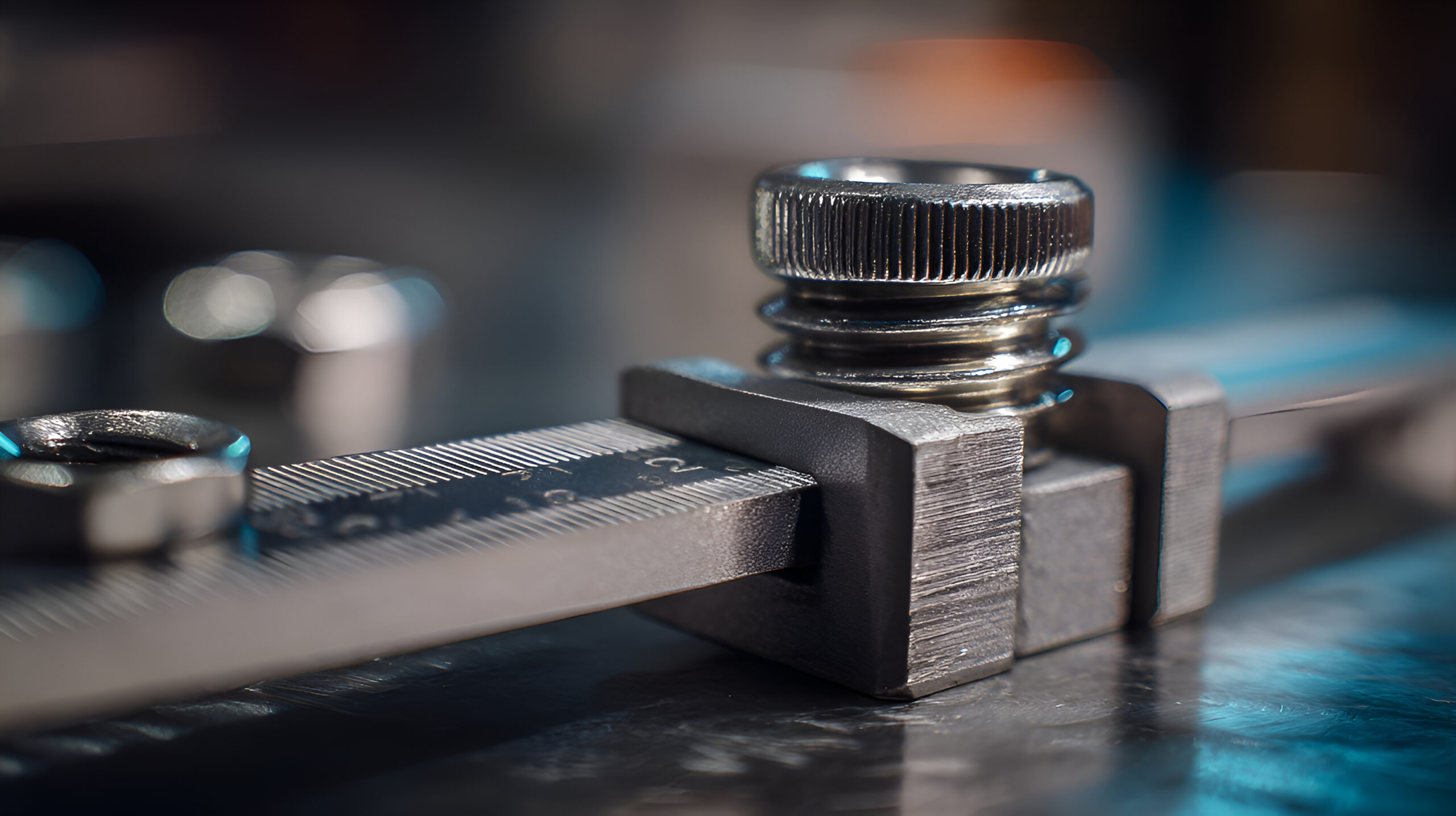

Professional caliper calibration relies on systematic multi-point verification to confirm accuracy across the instrument’s entire measurement range. Technicians test your calipers at various points using precision gauge blocks with certified tolerances, ensuring measurement uncertainty stays within acceptable limits.

The verification process includes:

- Zero-point confirmation validating baseline accuracy when jaws close completely

- Multi-range comparisons testing measurements at 25%, 50%, 75%, and 100% of capacity

- Correlation to standards comparing results against traceable reference materials

Each verification point documents deviations from true values, establishing your caliper’s actual performance characteristics. You’ll receive detailed reports detailing all measurement points, observed errors, and conformance status. This documented evidence proves your instrument’s reliability and supports quality management requirements across industries requiring precise dimensional measurements.

Battery Drift, Jaw Wear, and Contamination Problems Calibration Prevents

While digital calipers provide convenient readouts and enhanced functionality, they’re susceptible to specific failure modes that gradually compromise measurement accuracy. Battery voltage drift causes display readings to deviate from actual measurements, while environmental factors like temperature fluctuations and humidity affect dimensional stability of the instrument’s components.

You’ll encounter jaw wear from repeated contact with workpieces, creating measurement errors that compound over time. Metal chips, coolant residue, and dust contamination interfere with the slide mechanism, preventing proper jaw closure and zero-setting. User error compounds these issues when you don’t recognize degradation symptoms.

Regular calibration detects these problems before they escalate, ensuring consistent accuracy and maintaining measurement traceability throughout your quality control processes. Professional verification identifies specific failure modes requiring correction.

Should You Calibrate In-House or Use Accredited Services?

Once you’ve recognized the need for regular caliper calibration, you’ll face a decision between establishing in-house capabilities or partnering with accredited calibration laboratories. Method selection factors include equipment investment costs, technician training requirements, and your facility’s measurement uncertainties tolerance.

Consider these key advantages of accredited services:

- Traceability assurance – EML accreditation benefits include ISO/IEC 17025 compliance and NIST-traceable certificates

- Reduced overhead – Eliminate gauge block investments, training expenses, and calibration record keeping complexities

- Faster operations – Professional service turnaround times often beat in-house processing when accounting for technician availability

For most organizations, accredited laboratory partnerships deliver superior quality assurance without the infrastructure burden. You’ll maintain compliance confidence while focusing internal resources on your core manufacturing operations.

Trust EML Calibration for Precise Caliper Calibration Services

Your measurement accuracy depends on calibration you can trust. Don’t let worn jaws, battery drift, or contamination compromise your quality standards. Whether you’re running simple spot checks or managing complex compliance requirements, professional calibration services give you the traceability and documentation you need. Choose an accredited provider who understands your instruments and industry standards.

EML Calibration delivers ISO/IEC 17025:2017 accredited caliper calibration for vernier, dial, and digital models of all sizes, backed by NIST traceable gauge block standards and over 25 years of precision measurement expertise. We provide comprehensive calibration certificates and flexible service options including laboratory and on-site calibration. Contact us today to schedule your caliper calibration service—because precision isn’t optional when your reputation’s on the line.