Power supply calibration guarantees your equipment delivers the exact voltage and current specified, preventing component damage and measurement errors. You’ll need precision instruments like digital multimeters and calibrated loads to verify accuracy at multiple output levels.

Regular calibration compensates for component aging and environmental effects while maintaining compliance with quality standards. Different supply types (linear, switching, programmable) require specialized techniques to achieve ideal results. Proper calibration documentation provides essential traceability for your critical systems.

Understanding Power Supply Accuracy: Why Calibration Matters

While many engineers focus on a power supply’s rated specifications, the actual performance can deviate noticeably over time without proper calibration. This drift isn’t merely academic—it directly impacts your measurements, device functionality, and test reliability.

When your power supply delivers inaccurate voltage or current, it can damage sensitive components, create inconsistent test results, or cause intermittent failures that are difficult to diagnose. Even small deviations of 1-2% can drastically affect precision electronics.

Regular calibration guarantees your power supply maintains its specified accuracy, compensating for component aging, environmental effects, and normal wear. You’ll avoid the costly consequences of faulty measurements, failed components, and invalid test results while maintaining compliance with quality standards that require traceable measurement accuracy.

The Critical Effects of Improper Power Supply Calibration

Having established why calibration matters, let’s examine what actually happens when power supplies remain uncalibrated.

Uncalibrated power supplies can deliver voltages considerably higher than indicated, potentially damaging sensitive components or causing premature failures. You’ll likely experience erratic circuit behavior that’s difficult to troubleshoot since you’re working with incorrect baselines.

For test environments, uncalibrated supplies invalidate your results. How can you trust measurements when your reference power is inaccurate? This leads to costly development cycles and product failures.

Safety risks increase too. Power supplies with degraded isolation barriers or improper current limiting can create shock hazards or fire risks. Over time, these issues worsen as components age and drift further from specifications.

Don’t overlook calibration—it’s not just about precision but also reliability and safety.

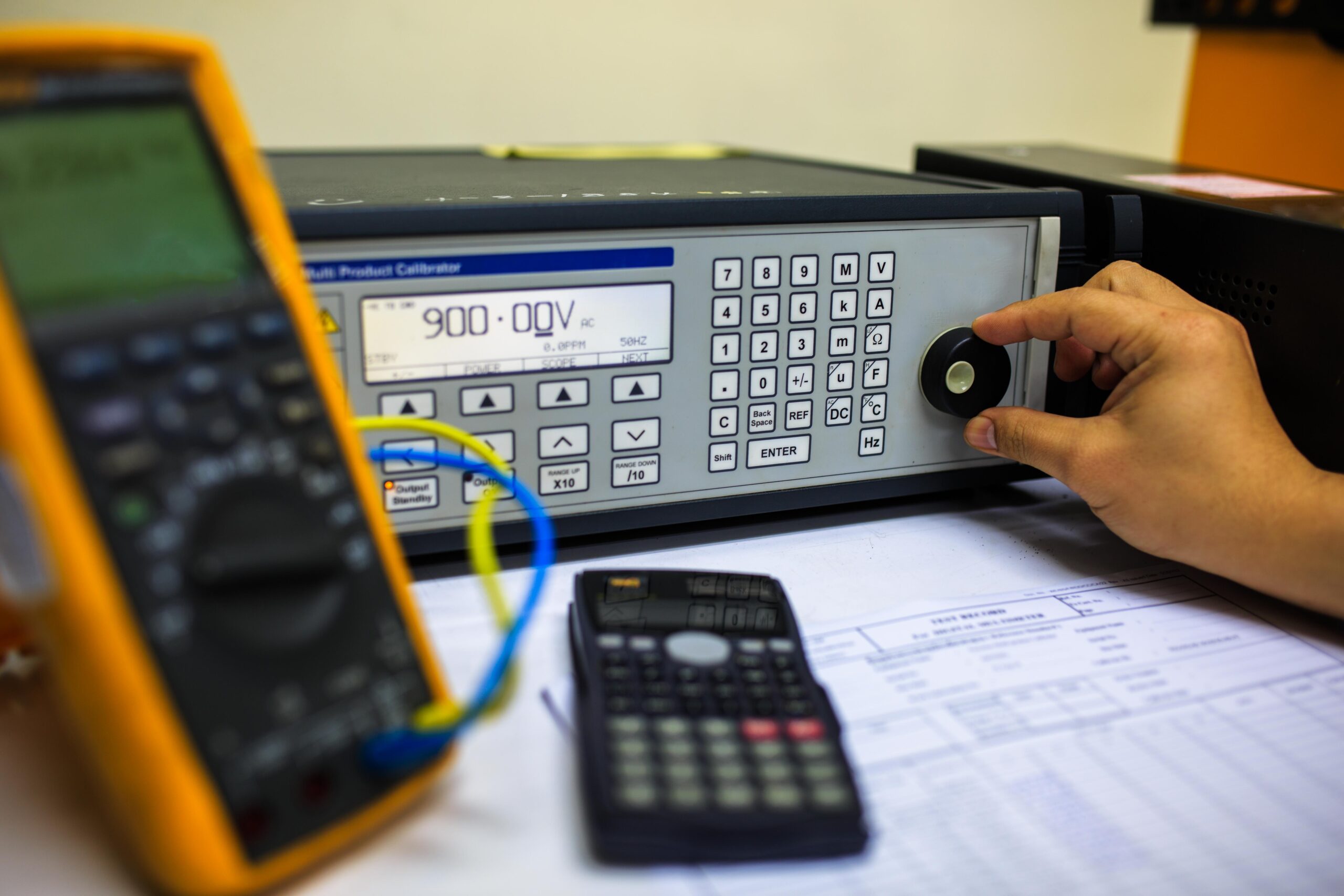

Essential Equipment and Standards for Power Supply Calibration

Every proper power supply calibration demands specific reference instruments and standardized procedures to verify accuracy. You’ll need a precision digital multimeter with at least 5½ digits resolution and 0.01% accuracy for voltage measurements up to the supply’s maximum rating.

For current calibration, precision current shunts or electronic loads with calibration certificates are essential. These should handle the full range of your power supply’s output capabilities.

Temperature and humidity monitoring equipment corroborates environmental conditions remain within acceptable parameters during calibration. You’ll also need proper cables with appropriate gauge and connectors to minimize measurement errors.

Most importantly, all reference instruments must be traceable to national standards with valid calibration certificates and uncertainty values lower than your calibration targets.

Voltage and Current Calibration: A Methodical Approach

Successful power supply calibration boils down to a systematic approach that eliminates variables and verifies repeatability. You’ll need to start with voltage calibration, connecting your reference standard in parallel with the power supply output while providing proper warm-up time for both instruments.

Begin at the lowest range, comparing displayed values against your reference standard at 10%, 50%, and 90% of full scale. Document all readings before proceeding to current calibration, where you’ll connect a calibrated electronic load in series with your precision current shunt.

For each measurement point, allow adequate settling time before recording values. Don’t forget to validate both sourcing and sinking capabilities if your power supply offers bidirectional functionality. This methodical process confirms your measurements remain traceable to national standards.

Measuring and Calibrating Ripple and Noise Parameters

Most power supply specifications include ripple and noise ratings, but these critical parameters require careful measurement techniques for accurate calibration. You’ll need an oscilloscope with sufficient bandwidth (typically 100MHz or higher) and a properly terminated coaxial probe to avoid measurement artifacts.

When measuring ripple, use AC coupling and set your bandwidth limit to 20MHz to isolate true power supply noise from external RF interference. Create a consistent setup with twisted measurement leads kept perpendicular to power cables to minimize induced noise.

For calibration, compare your measurements against a traceable standard power supply with known ripple specifications. Document both peak-to-peak and RMS values, as they represent different aspects of noise performance. Always measure ripple under various load conditions to guarantee exhaustive characterization.

Specialized Techniques for Different Power Supply Types

While ripple and noise measurements apply to all power supplies, each type requires its own calibration approach based on its unique architecture.

For linear power supplies, focus on thermal stability during calibration as their performance depends heavily on temperature. Allow adequate warm-up time before measurements.

With switching power supplies, you’ll need specialized bandwidth-limited equipment to accurately capture high-frequency artifacts. Pay particular attention to load regulation testing across multiple load points.

Programmable supplies demand additional verification of their digital interfaces and command response times. Test their transient recovery across their full output range and verify remote sensing functionality.

Multi-output supplies require checking for cross-regulation issues when one output experiences load changes while monitoring others for stability.

Documentation and Traceability in Calibration Processes

Proper documentation forms the backbone of any effective power supply calibration program. You’ll need to maintain detailed records that establish an unbroken chain of traceability back to national standards. This documentation isn’t just bureaucratic paperwork—it’s your protection against liability and your proof of compliance with industry regulations.

Calibration certificates must include measurement results, uncertainties, and reference to the standards used. Your documentation should track environmental conditions during calibration (temperature, humidity). Implement a version-controlled procedure system that captures methodology changes over time. Establish clear deviation protocols that document how to handle out-of-specification measurements.

Well-maintained calibration records allow you to analyze performance trends, anticipate failures, and optimize your calibration schedule based on actual drift patterns rather than arbitrary timeframes.

Preventative Maintenance to Extend Calibration Intervals

Regular maintenance between formal calibrations can greatly extend your power supply’s accuracy and stability intervals. Focus on keeping cooling systems clear of dust and debris, as temperature fluctuations profoundly impact internal reference components.

Check all connections monthly for corrosion or loosening that could affect measurement accuracy.

Monitor your power supply’s performance by running simple verification tests against a known good load. This helps you detect drift before it affects your measurements. You’ll also want to keep the unit’s environment stable—avoid humidity extremes and sudden temperature changes that accelerate aging of critical components.

Implementing these practices not only reduces calibration frequency requirements but also minimizes unexpected failures during critical operations, ultimately saving you time and resources.

In-house vs. Professional Calibration: Making the Right Choice

Deciding between in-house and professional calibration services requires careful evaluation of your organization’s resources and technical requirements. While in-house calibration offers immediate access and potential cost savings for high-volume needs, professional services provide specialized expertise and traceable certifications that may be required for regulatory compliance.

- Equipment investment costs versus recurring professional service fees

- Staff training requirements and maintaining calibration expertise

- Traceability requirements for your specific industry regulations

- Risk assessment for critical applications where calibration errors could be costly

Your decision should balance immediate budget constraints against long-term reliability needs. For non-critical applications with moderate accuracy requirements, in-house calibration may suffice, while precision instruments and mission-critical power supplies often justify professional calibration services despite higher costs.

Powering Success Through Precision Calibration

Power supply calibration is a critical investment that extends equipment life, ensures measurement integrity, and prevents costly component failures that could disrupt your operations. By establishing a systematic calibration schedule based on your equipment’s criticality and usage patterns, you protect sensitive components from damage while maintaining the voltage and current accuracy that your systems depend on. The modest cost of regular calibration prevents expensive measurement errors, failed components, and invalid test results that can cascade throughout your entire operation.

Don’t wait for power supply failures to impact your critical systems—proactive calibration is your first line of defense against equipment degradation and measurement uncertainty. Contact EML Calibration today to leverage their specialized expertise in power supply calibration, backed by ISO/IEC 17025:2017 accreditation and NIST traceable standards.

With over 25 years of proven experience in electronic calibration and flexible on-site or laboratory service options, EML Calibration delivers the precision, documentation, and traceability your power supply systems require to maintain peak performance and regulatory compliance.