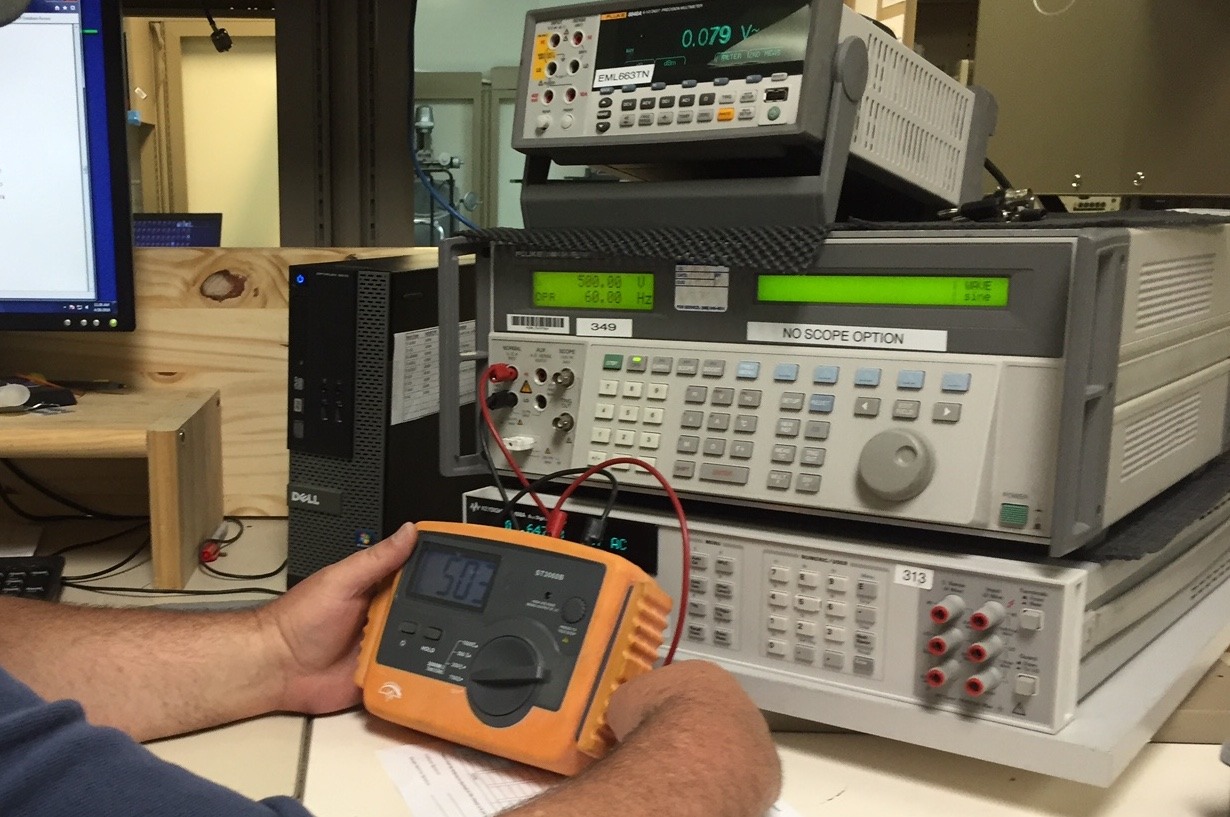

In many disciplines, whether engineering or scientific research, accuracy measurements depend heavily on electronic instrument calibration. The complexity of electronic calibration is explored in this article, with a specific emphasis on oscilloscopes, signal generators, and sensors.

This article is just to give readers a clear grasp of the significance and procedures of electronic calibration. Thus, it delves deeply into the fundamental components of each calibration procedure. Additionally, it investigates the various approaches used in complicated electronic setups. This knowledge is similar to the secret ingredient that ensures correct data collection and results in technological gadgets.

Marvel of Electronic Calibration in Achieving Accurate Measurements

Electronic calibration emerges as the unsung hero, playing a pivotal role in the quest for exact and dependable measurements. Additionally, error analysis is crucial in electronic calibration for locating and calculating measurement process uncertainties.

Precision measurement calibration standards offer reference points for calibrating equipment, enabling traceability and result comparison. In electronic calibration, traceability is crucial because it links the quantity being measured and national or worldwide measuring standards, assuring consistency and comparability across various labs and measurement systems.

Due to signal distortion, interference, and impedance matching, electronic calibration for high-frequency applications presents difficulties.

Software plays a crucial part in electronic calibration because it makes automation, data analysis, and correction algorithms possible, which raises measurement efficiency and accuracy.

Know the Fundamentals of Oscilloscope Calibration

A thorough grasp of the essential concepts and procedures employed to guarantee the precision and dependability of this equipment is required to calibrate measuring devices.

Accurate measurements are essential for oscilloscopes’ many uses in electronics, telecommunications, and research industries. Therefore establishing calibration standards is necessary to get factual findings. These standards include traceability specifications that relate the measured values to widely used units.

Calibration techniques entail:

- Evaluating the oscilloscope’s performance in comparison to these requirements.

- Adjusting as required.

- Maintaining a record of any process irregularities or uncertainties.

The bandwidth, rise time, voltage sensitivity, and time-based stability affect oscilloscope accuracy.

Since measurement uncertainty quantifies the ranges within which measurements may be regarded as trustworthy, it plays a crucial role in electronic instrument calibration. For oscilloscopes to be used to make accurate and reliable electrical measurements, it is imperative to comprehend these ideas.

Signal Generators are Calibrated for Accurate Output

Through a careful calibration procedure that assures the dependability and quality of the generated signals, signal generators may produce precise data. Frequency stability, amplitude accuracy, phase coherence, distortion reduction, and signal purity are some of the crucial components of the calibration process.

The capacity of a signal generator to sustain a constant output frequency over time is known as frequency stability. This is essential for applications that need accurate and reliable frequency signals.

How precisely the signal generator generates signals with the appropriate amplitude levels is known as amplitude accuracy. Additionally, the output amplitudes are perfectly matched to the prescribed values, thanks to calibration.

Maintaining continuous phase connections between various signals and components is called phase coherence. Thus, these phase connections will be precisely preserved throughout the signal-generation process thanks to calibration.

The distortion correction process entails making up for any undesirable distortion the signal generator introduces. These distortions can be found and removed by calibration for reliable output signals.

Another crucial calibration component is signal purity, which defines how free and clear the produced signals are of undesirable harmonics or noise. Signal generator calibration ensures pure, high-quality output signals suited for various applications demanding accurate and trustworthy measurements.

Techniques for Sensor Calibration for Trustworthy Data Acquisition

- Utilizing sensor calibration procedures to get accurate and consistent readings is essential for reliable data collection.

- Calibration of the temperature is essential for the best sensor performance. This entails altering the sensor’s output by the output of a reference standard at a known temperature.

- Pressure calibration procedures often use deadweight testers or pressure standards to get precise results.

- Methods for calibrating humidity sensors entail exposing the sensor to surroundings with regulated humidity levels. Then compare the results to measurements from a calibrated reference device.

- By exposing vibration sensors to known vibration levels and altering their output accordingly, vibration sensors must be calibrated to achieve accurate results.

- Last, gas sensors may be calibrated to increase sensitivity by subjecting them to known gas concentrations and modifying their response curves.

These diverse calibration methods allow sensors to deliver precise and dependable data for various applications.

Complex Electronic Systems: Advanced Calibration Methods

Innovative techniques must be developed and put into use to ensure sensor calibration accuracy due to the complexity of electronic systems. Due to complicated electronic systems, several sophisticated calibration procedures have been designed to meet this demand.

Calibrating Multiple Channels for Super-Powered Gadgets

This excellent method tackles calibrating many channels simultaneously, ensuring all the measurements are spot-on. It’s like having a team of synchronized sensors, perfect for situations where many sensors need to work together seamlessly.

Continuous real-time sensor calibration approaches for dynamic electronic systems

These techniques enable modifications to be performed when ambient circumstances change, or system parameters drift. Thus, guaranteeing that sensor measurements are dependable and precise throughout the process.

Non-linear calibration approaches for intricate electronic circuits

Conventional linear calibration methods might not be enough for precisely calibrating non-linear parts or circuits that exhibit unfavorable behavior. However, non-linear calibration techniques consider the non-linear properties of these circuits, producing more accurate measurement outcomes.

Modern calibration techniques, time base generator calibration, and sophisticated algorithms are essential to minimize measurement errors in electronic systems. Additionally, they guarantee the dependability and quality of sensor data collection.

Frequently Asked Questions

What Problems Do Calibration of Electronics Typically Face?

- Typical difficulties with electrical calibration include:

- Choosing the proper calibration methods and tools.

- Controlling the calibration’s uncertainty.

- Select suitable calibration intervals.

- Maintaining accurate calibration records.

These challenges require technical expertise, precision, and attention to detail.

What is the recommended calibration period for electronic instruments?

Depending on the type of instrument, how it is used, and the environment, several frequencies are advised for electronic instrument calibration. The calibration period should be chosen based on these considerations, but regular calibration is necessary to guarantee accurate results and guard against any mistakes.

Do you have any specific criteria or advice for calibrating electrical devices?

Via calibration certifications, standards, and guidelines to retain traceability, consider crucial operational factors. Additionally, I understand measurement uncertainty, embrace automation advancements, and guarantee adherence to industry standards.

Is it recommended to hire expert calibration services, or may electronic calibration be completed internally?

For electronic calibration, less expensive methods like do-it-yourself techniques could be considered. But using a professional calibration service has advantages like knowledge and accuracy. Tips for in-house calibration include appropriate training and calibrated equipment maintenance. However, depending on the requirements, several calibration tools are recommended.

What are the potential effects of ignoring regular electronic instrument calibration?

The following are possible effects of not routinely calibrating electronic instruments:

- Accuracy compromised.

- Data integrity issues.

- Greater possibility of device failure.

- Decreased trustworthiness.

- Violation of industry regulations.

For the best performance, calibration must come first.

Are you prepared to advance your knowledge of electrical calibration? Whether you’re an engineer, researcher, or hobbyist, EML Calibration can significantly improve the precision and dependability of your measurements. You can put your newfound knowledge into practice and attain perfection in electronic calibration. Don’t let uncertainties and errors undermine your findings. Also, please remember that calibration is the first step in accuracy.

Contact us right now to start your path toward more precise measurements and to learn more about the vast world of electrical calibration!