Maintaining the accuracy and dependability of devices used in numerous industries requires business calibration services. Businesses may depend on precise data for decision-making and quality control by accurately calibrating measuring instruments.

By offering an unbiased and technical overview of their importance, advantages, and best practices, this article seeks to demystify calibration services.

Experiments in research, production, product development, and regulatory compliance rely primarily on precise measurements for businesses across all industries. Calibrate your devices as soon as possible to avoid inconsistent readings that might result in poor decisions or subpar products. For sectors where adherence to standards is required, faulty measurements may have legal repercussions. Precise calibration is crucial to guarantee that companies achieve their objectives while upholding high levels of precision and reliability.

This blog will go into the complexity of the calibration services sector. The importance of calibration in business, the benefits of frequent calibration, and best practices for selecting a calibration service provider are some topics covered in this article. By learning about these topics, the reader will better grasp how such services contribute to the precision and reliability of equipment.

Value of Calibration Services

Understanding the value of calibration services in business operations and how they affect overall performance enables firms to make wise decisions about instrument maintenance strategies. Regular calibration provides a variety of benefits that directly support company growth. These advantages include improved measurement accuracy, reduced chances of inaccurate readings or non-compliance issues, increased customer satisfaction thanks to reliable product quality assurance, and improved operational efficiency thanks to reduced production errors brought on by incorrect measurements or equipment malfunctions.

It is essential for organizations to carefully choose reliable calibration service providers to enjoy these benefits altogether. These companies should use cutting-edge technology, comply with industry standards, and hire field experts. Companies can maximize their calibration efforts by collaborating with such service providers and maximizing benefits.

Calibration Services: What Are They?

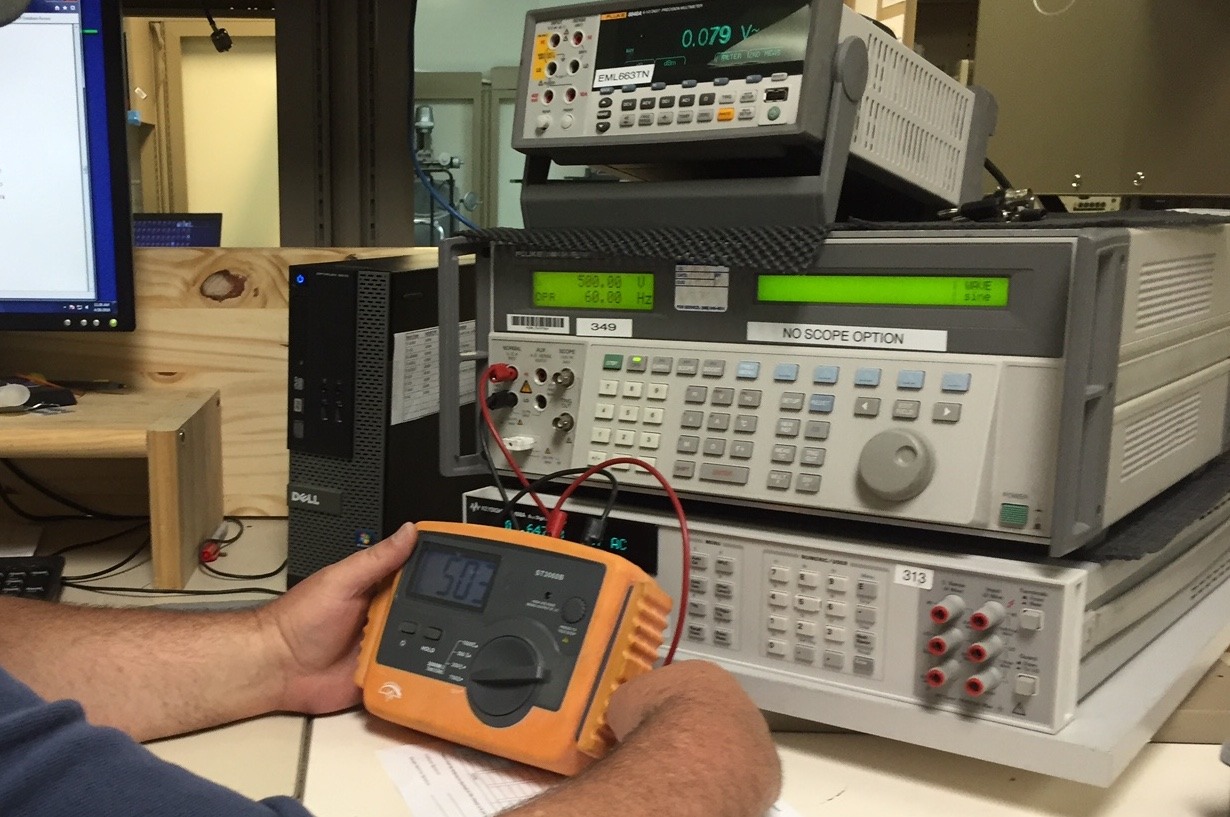

By comparing measurements made by equipment to accepted standards, calibration services cover a variety of methods intended to ensure the accuracy and dependability of the devices. Usually, calibration businesses or labs specializing in metrology, the measuring science, offer these services.

The advanced tools and skilled staff at metrology labs allow them to precisely measure and calibrate various instruments.

Tool calibration is a crucial component of calibration services. Tools like torque wrenches, pressure gauges, and temperature sensors need to be calibrated often to provide accurate readings. Tool calibration services entail comparing the tools to recognized standards and, if necessary, correcting them. This guarantees that the equipment operates within reasonable limits and generates accurate findings.

Other instruments, like oscilloscopes, multimeters, and spectrometers, can also benefit from calibration services by having their accuracy in detecting electrical signals, voltage levels, or chemical compositions confirmed.

Overall, these services are essential for preserving the accuracy and integrity of instruments in various sectors.

Importance of Business Calibration Services

Businesses place great importance on the careful calibration of instruments to ensure their accuracy and dependability. This promotes trust in the data gathered and helps decision-making processes. Companies may acquire accurate and trustworthy results thanks to calibration services, guaranteeing that measuring tools are precisely calibrated to established standards.

This is especially important for industries like manufacturing and medicine, where accurate measurements are necessary for quality control. To fully comprehend the benefits of calibrating in business, take into account the following:

Compliance

Firms are obliged by various sectors’ stringent rules and standards to calibrate their equipment regularly. Calibration ensures compliance with these regulations, avoiding any legal issues or penalties.

Quality Assurance

Accurate measurements ensure the product’s uniformity and quality. Calibration helps businesses address issues before they affect the caliber of their products by spotting inconsistencies or flaws in measurement instruments.

Cost Savings

Companies may avoid waste, improve processes, and save costs related to rework or rejected items by maintaining precise measurements through routine calibration.

Maintaining instrument accuracy and dependability in enterprises requires calibration services from reliable firms in your area. They support regulatory compliance, offer quality assurance for goods and processes, and facilitate cost savings through effective operations.

For accurate data gathering and well-informed decision-making in any corporate context, engaging in effective calibration methods, whether using onsite calibration services or requesting metrology calibration services from a professional source, is imperative.

Advantages of Routine Calibration

Businesses may experience improved quality control, operational efficiency, and more affordable decision-making procedures by routinely calibrating their measurement equipment. Because calibration ensures that the measurements gathered by organizations are precise and reliable, businesses may have confidence in their data. By frequently calibrating their equipment, companies can uphold consistent quality control requirements. This matters in industries like manufacturing and medicine, where precision and accuracy are crucial.

To prevent errors or defects in products or services, calibration helps to identify any deviations or faults in instrument readings. Additionally, routine calibration helps a firm run more efficiently. When appropriately calibrated, equipment offers accurate readings that facilitate effective procedures and prevent resource loss. Regular calibration, for instance, ensures that every step is carried out precisely and consistently in manufacturing processes where tools and equipment must be accurately calibrated for specific machining operations. This increases output and decreases rework or waste materials due to measurement errors.

Therefore, firms may optimize their operations for optimal output by investing in calibration services or calibration laboratories nearby for regular instrument inspections and adjustments. Businesses can gain various advantages from routine measurement instrument calibration, including improved quality control procedures, increased operational efficiency due to accurate measurements in crucial processes like manufacturing operations or medical diagnostics, and cost-effective decision-making based on reliable data from calibrated instruments. It is advised that firms use expert metrology laboratories or tool calibration services to perform these crucial duties regularly to guarantee the greatest accuracy and dependability in instrument readings. By doing so, companies can avoid problems caused by inaccurate measurements while maintaining a competitive edge in their respective industries.

Choosing the Right Business Calibration Services Provider

Choosing the proper calibration service provider can considerably impact the reliability and accuracy of measuring devices used in various sectors. There are several choices for calibration, including metrology labs, mobile calibration services, onsite calibration services, and electronic calibration.

Metrology Labs

A metrology laboratory is a specialized space with cutting-edge tools and knowledge to offer exact calibrations. These labs often adhere to exacting quality standards and may be traced to regional, national, or global standards. They provide thorough instrument calibration services that guarantee great accuracy and dependability.

Mobile Calibration

On the other hand, mobile calibration services provide convenience by bringing the calibration procedure right to the customer’s location. This alternative is advantageous when bringing equipment to a scientific facility may take time and effort. Mobile calibration services make effective on-site calibrations using portable equipment and knowledgeable specialists.

Onsite Calibration

By calibrating the customer’s property, onsite calibration services can provide comparable benefits. By doing this, the need to transfer instruments is removed while still providing precise findings.

Electronic Calibration

Electronic calibration focuses on calibrating electronic devices such as oscilloscopes, multimeters, or signal generators. It requires specialized knowledge and equipment specific to electronics. Electronic calibration providers specialize in this field and often have experience working with complex electronic instruments.

Nationwide Gage Calibration

Lastly, nationwide gage calibration providers offer widespread coverage across different regions or states within a country. These providers have multiple locations strategically placed throughout the nation, making it convenient for customers from various areas to access their services easily.

Choosing the right calibration service provider is vital in maintaining accurate measurements. When selecting a metrology lab for thorough calibrations or choosing mobile or onsite services for convenience, it is essential to consider aspects like experience, traceability to standards, and adherence to quality guidelines. While countrywide gage suppliers offer accessibility across various places, electronic-specific calibrations may necessitate professionals with unique expertise in electronics. Organizations may guarantee the accuracy and dependability of their measuring tools by carefully choosing the right calibration service provider.

Optimal Procedures for Business Calibration Services

Using best practices can help you get calibrated results that are accurate and dependable. Following these recommended practices may guarantee that instruments are calibrated appropriately and deliver accurate readings when it comes to EML calibration or meter calibration services:

Regular Calibration Timetable

Create a timetable for calibrating equipment by manufacturer advice or professional standards. Thus guaranteeing that agents are calibrated at the proper intervals to preserve accuracy.

Appropriate Handling and Storage

Instruments should be handled with care to avoid damage during usage or transit. Additionally, they should be kept in a regulated atmosphere free of vibrations, high humidity, and other factors that could impair their operation.

Traceability

Check to ensure the calibration service provider adheres to traceable standards and provides traceability documentation. Additionally, ensuring that the calibration procedure is carried out using credible reference standards increases the accuracy of the calibration results.

Qualified Technicians

Seek out a calibration service company that employs qualified technicians with previous expertise in a specific instrument type. They should receive training in proper calibration procedures and become knowledgeable about all relevant regulations and standards.

In-depth Business Calibration Certificates

Request complete calibration certifications from the service provider. The original and final measurements, uncertainties, traceability information, and any calibration adjustments must all be included in these certificates.

Organizations may ensure that their instruments are accurately calibrated and provide correct data by following these best practices for EML calibration or meter calibration services. Maintaining accuracy in instrumentation involves following a regular schedule, treating equipment appropriately, assuring traceability, hiring competent personnel, and acquiring thorough calibration certifications.

Some Frequently Asked Questions

Can I conduct business calibration services independently without contracting with a qualified calibration service provider?

It is necessary to contract with an expert supplier to provide calibration services. Calibration calls for technical know-how, specialized tools, and adherence to set protocols to assure accuracy and dependability in instruments.

How frequently should business calibration services be carried out for various instruments?

Calibration services should be conducted at regular intervals depending on the kind of device. However, calibration frequency varies depending on instrument usage, surrounding environment, and manufacturer standards to provide accurate and dependable results.

Are there any laws or regulations for calibrating services for particular businesses?

Different sectors have rules and requirements regarding the legal elements of calibrating services for specific organizations. These requirements were established to guarantee precise and trustworthy measurements while conforming to safety standards and legal requirements that governing agencies enforce. For example, calibration services must abide by stringent requirements in healthcare and aviation to guarantee the highest accuracy and safety.

What typical variables can impact the precision and dependability of equipment calibration?

Environmental factors, such as fluctuations in temperature and humidity, mechanical wear and tear, electrical interference, operator mistake, and inappropriate instrument maintenance or handling, can affect instrument calibration’s accuracy and reliability.

Are there alternative technologies or calibrating methods that could be more effective than existing ones?

Alternative calibration techniques and technologies have advantages over more traditional ones. Some examples are self-calibration capabilities that increase process efficiency and accuracy, automated calibration systems that do away with human mistakes. Additionally, remote calibration capabilities that make it easy to access equipment in inaccessible places.

Are you ready to make sure accurate and reliable measurements for your business?

Contact EMLA (Electronic Metrology Laboratory) today and benefit from our state-of-the-art calibration services. Maximize your operational efficiency, maintain compliance with industry standards, and make confident decisions based on precise data. Don’t compromise on accuracy—partner with EML for top-notch calibration solutions. Reach out now to schedule your calibration services.